Rozwiązania CAREL do odzysku ciepla w centrach danych

CAREL oferuje szeroką gamę rozwiązań dla jednostek chłodzących w centrach danych, które wykorzystują zasadę pośredniego chłodzenia wyparnego (IEC).

Grupa produktów CAREL Group obejmuje technologie o wysokiej wydajności opracowane na przestrzeni wielu lat doświadczeń w tym sektorze, dzięki czemu zapewnione są znaczne oszczędności energii.

Oprócz tradycyjnej gamy sterowników i wyświetlaczy, które sa mózgiem systemu, Grupa CAREL oferuje również wymiennik ciepła powietrze-powietrze Recuperator B Blue, prawdziwe serce systemu. Synergia z atomizerem KEC oznacza, że chłodzenie wyparne można stosować dokładnie tam, gdzie jest najbardziej potrzebne, tak jak w ludzkim układzie krążenia. Szeroka gama akcesoriów, od czujników po elektroniczne zawory rozprężne i sterowniki sprężarek BLDC, uzupełnia elastyczną i modułową ofertę do opracowywania różnych wariantów tych jednostek.

![]()

Zintegrowane rozwiązania sterujące

KEC to chłodznica pary wodnej, która rozpyla wodę za pomocą pompy i wysoce elastycznego systemu dystrybucji dysz, który można dostosować do układu różnych jednostek. Pompa charakteryzuje się pracą o zmiennej prędkości napędzaną przez inwerter i jest zarządzana przez sterownik (dostępny na osobnym module dla elastyczności instalacji), który optymalizuje dostarczanie wody; stelaż dystrybucji jest niezwykle elastyczny, aby dostosować się do układu różnych jednostek IEC; dysze dystrybucyjne mogą być wyposażone w specjalne deflektory, które zwiększają turbulencje powietrza, aby lepiej rozprowadzać krople wody w strumieniu powietrza.

Wszystko to pozwala na wykorzystanie szczególnych zalet układów rozpylających, w szczególności w porównaniu z tzw. „mediami zwilżanymi”, jak np. możliwość odparowania w kontakcie z powierzchnią wymiennika ciepła.

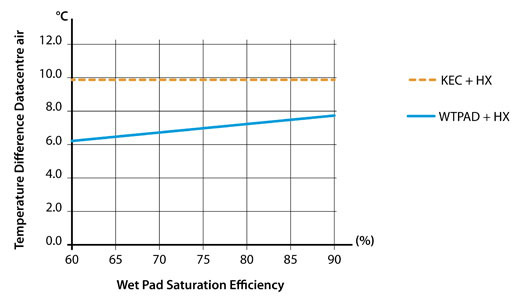

Porównanie systemu rozpylania i zwilżonych mediów

Poniższy wykres przedstawia porównanie między efektem parowania tylko w powietrzu (uzyskiwanym również za pomocą wetted media) a możliwością zwilżenia powierzchni wymiennika ciepła, przy takim samym nasyceniu powietrza, przy użyciu systemu rozpylania: poprawa wynosi 25% w najgorszym przypadku.

po stronie powietrza wywiewanego z pomieszczenia przed wymiennikiem odzysku ciepła montowany jest system nawilżania z dyszami rozpylającymi wodę lub system nawilżający z innym zraszanym medium

Powietrze ( air only ) przechodząc przez ten punkt nawilżania wyparnego, obniża swoją temperaturę ( proces chłodzenia adiabatycznego ) jednocześnie zwiększając zawartość wilgoci, czyli wysycenie . W ten sposób powietrze wchodzące na wymiennik odzysku ciepła ma już obniżoną temperaturę, dzięki czemu sprawność chłodnicza wymiennika ulega podwyższeniu.

Jeszcze lepszy efekt uzyskuje się, kiedy natryskujemy wodę bezpośrednio na wymiennik. Wówczas powstaje wilgotna powierzchnia. Wydłuża to drogę kontaktu powietrza z filmem wodnym i zwiększa się efektywność.

Zalety:

Wyższa efektywność absorpcji dzięki mniejszym kroplom;

Wyższa efektywność absorpcji dzięki mniejszym kroplom;

Lepsza kontrola temperatury dzięki pompie o zmiennej częstotliwości (Variable-frequency Pump) oraz szybszej reakcji wynikającej z mniejszej bezwładności;

Lepsza kontrola temperatury dzięki pompie o zmiennej częstotliwości (Variable-frequency Pump) oraz szybszej reakcji wynikającej z mniejszej bezwładności;

Niższe straty ciśnienia, co przekłada się na niższe TCO dzięki mniejszemu zużyciu energii przez wentylator;

Niższe straty ciśnienia, co przekłada się na niższe TCO dzięki mniejszemu zużyciu energii przez wentylator;

Zmniejszone wymagania konserwacyjne, ponieważ nie ma potrzeby okresowej wymiany, jak w przypadku wkładów nawilżających, a także gwarancja braku namnażania się bakterii;

Zmniejszone wymagania konserwacyjne, ponieważ nie ma potrzeby okresowej wymiany, jak w przypadku wkładów nawilżających, a także gwarancja braku namnażania się bakterii;

Bezpośrednie chłodzenie wyparne poprzez zwilżanie powierzchni wymiennika ciepła może poprawić jego wydajność.

Bezpośrednie chłodzenie wyparne poprzez zwilżanie powierzchni wymiennika ciepła może poprawić jego wydajność.

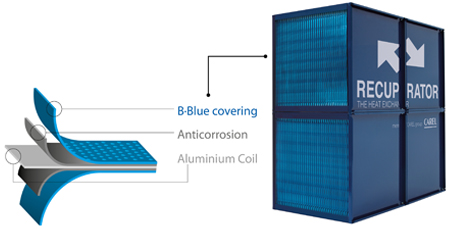

Wymiennik ciepła

B Blue to wymmienik ciepła z sekcjami wykonanymi z aluminium ze specjalna powłoką zaprojektowaną dla tego rowiązania. Optymalizuje wymianę ciepła i zwiększa efekt parowania dzięki zwilżaniu powierzchni; wszystko to w połączeniu z doskonałą szczelnością (testowaną na każdym produkcie) oraz wyjątkową niezawodnością w czasie, gwarantowaną przez odporność na korozję.

Benefity powłoki B-Blue

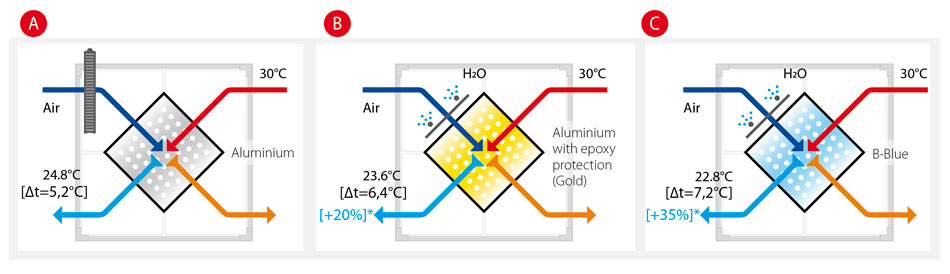

Projekty badawcze prowadzone wspólnie z Politechniką Mediolańską wykazały, że rozpylanie kropli wody na wymiennik ciepła (B) zwiększa wydajność chłodniczą o 20% w porównaniu z tradycyjnymi systemami adiabatycznymi, takimi jak zwilżane media, które ograniczają się do nasycania powietrza (A). Woda rozpylona na wymienniku ciepła nadal odparowuje, wydłużając efekt chłodzenia na całym przepływie powietrza przechodzącym przez wymiennik. Najczęściej stosowaną ochroną antykorozyjną jest powłoka epoksydowa GOLD: zastąpienie jej innowacyjną powłoką B Blue przynosi znaczące korzyści. Powłoka B Blue wykazuje właściwości hydrofilowe, co pozwala na lepsze rozprowadzenie kropli na powierzchni, zwiększając jej zwilżalność, a w konsekwencji prowadzi do dalszego 15% wzrostu wydajności (C). Dodatkowo podkład antykorozyjny zapewnia niezawodność produktu.

FIND OUT MORE ABOUT THE PRODUCT