Przemysł winiarski: magazynowanie i chłodzenie

produkt

tradycja z owoców

Smak i aromat sa rezultatem nie tylko jakość winogron, ale także mikroklimatu w miejscu gdzie wino jest produkowane, gdzie dojrzewa i jest sprzeddawane.

Temperatura powietrza i kontrola nawilżania

mają znaczenie fundamentalne la zachowanie cech

organoleptycznych wina przez cały okres jego życia.

W czasie wzrastającej konkurencji na rynku, używanie najbardziej wyrafinowanych technologii pozwala na produkcję wina wysokiej jakości. Zapewnienie odpowiedniego nawilżenia i temperatury oraz możliwości monitorowania i porównywania tych wartości podczas sezonu są kluczowymi elementemi w procesie produkcji wina oraz tworzenia charakteru wina dla każdego rocznika.

Carel, jest liderem sterowników dla chłodnictwia i klimatyzacji oraz systemów nawilzania, To idealny partner dla przemysłu winiarskiego. With a vast range of standard and custom solutions, CAREL can respond to the needs of the wine industry with experience and professionalism, supplying cutting-edge global technical support through its extensive network in numerous countries around the world.

High efficiency and hygiene

High efficiency and hygiene

CAREL adiabatic humidification systems can provide the right level of humidity constantly and precisely, with extremely low energy consumption and in compliance with hygiene requirements.

Integration

Integration

CAREL’s complete solutions can fulfil all control, integration and supervision requirements for room air-conditioning systems.

Lower energy consumption and environmental impact

Lower energy consumption and environmental impact

CAREL solutions are high efficiency, aimed at reducing energy consumption and consequently temperature and humidity control system running costs.

Less pollutants in the atmosphere and a lower environmental impact of the winemaking process.

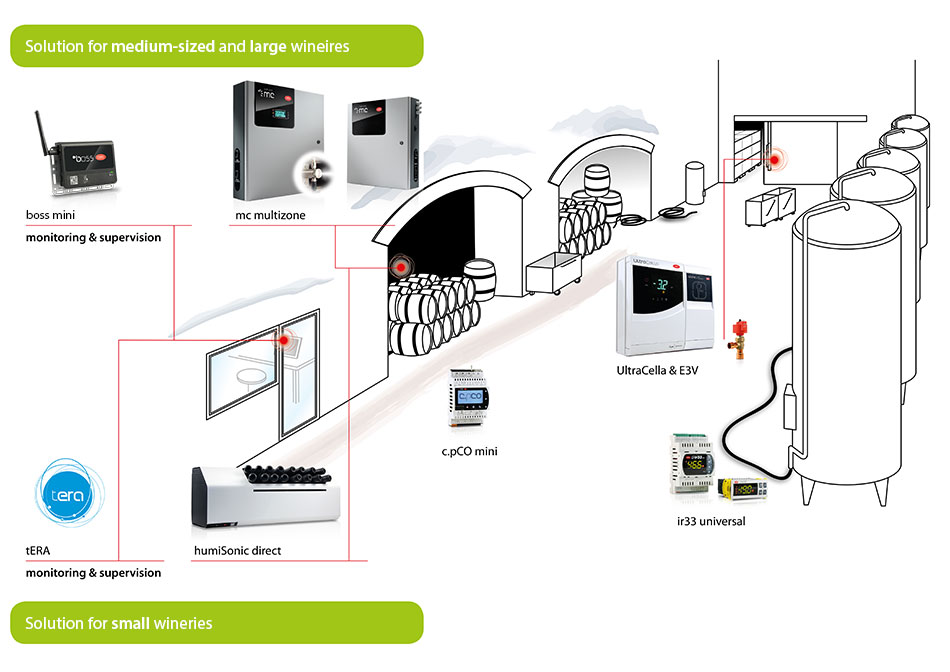

MC multizone

MC multizone is the CAREL compressed air adiabatic humidifier that delivers atomised water directly into the room, making it ideal for large wineries and barrel cellars.

The special technology used for the stainless steel atomising nozzles means MC delivers very fine droplets, which are easily absorbed by the air in a small space, even at lower temperatures.

The automatic line flushing procedure and the “self-cleaning” nozzles make MC completely hygienically safe product.

humiSonic direct

humiSonic direct is the new solution for direct room humidification that exploits innovative ultrasound technology.

humiSonic direct incorporates, in just one compact solution, all the components needed for operation, making it the best proposal on the market in terms of ease and flexibility of installation, for both new systems and the retrofit of existing buildings.

CAREL ultrasound technology minimises energy consumption, while at the same time reducing maintenance, thanks to the extraordinary lifespan of the piezoelectric transducers (up to 10,000 h). Hygiene is moreover guaranteed by the use of stainless steel components and automatic washing and filling cycles.

With Modbus compatibility available as standard, humiSonic direct can communicate with any control system, easily integrating with the rest of the installation.